Contact us

For More Information

Do you have questions for Cool Caps, would you like to know more about a product or service, or leave us a message?

bbh

bhjb

coolcaps2015@gmail.com

033 4070 3238

UTTARAKHAND

Plot E2A, Sector - 1, IIE, Sigaddi Growth Centre, Kotdwar, Pauri Garhwal - 246149, Uttarakhand

UTTARAKHAND

Plot E2A, Sector - 1, IIE, Sigaddi Growth Centre, Kotdwar, Pauri Garhwal - 246149, Uttarakhand

ODISHA

TELANGANA

ASSAM

Jab Jab Kuchi Industrial park, Village : Jab Jab Kuchi, P.O.: Barajol, PS: Ghograpar, Dist-Nalbari, PIN: 781369

Annapurna Apartment, 23, Sarat Bose Road, 1st Floor, Suite no. 1C, Kolkata -700020

West Bengal

Saraswati Complex, Vill: Nimerhati, P.S. - Domjur, P.O. - Makardah, Howrah - 711409

ANSWERS

Frequently Asked Questions

The Company embarked on the commissioning of Unit III of Cool Caps in Kotdwar, Uttarakhand. The Company has generally focused on commissioning integrated manufacturing complexes comprising a range of products within a single location, enhancing economies of scale and customer engagement.

This unit comprised the manufacture of carbonated soft drink single piece caps, the Company invested in a 24 cavity ACMI machine with an installed capacity of 2.50 Crore caps a month and I am pleased to state that the product is completely sold out and the Company touched rated capacity utilisation within six months of commissioning. The Uttarakhand unit also commissioned a bottle preform unit with an aggregate capacity of 35 tonnes per month. The unit is addressing two sizes – 5 and 10 litres – and I am pleased to state that here too the capacity has been completely sold to a large Indian mineral water brand. The response has proved so encouraging that the management has already placed an order for the second preform machine to be commissioned at the same location. The management commissioned an injection moulding machine to manufacture bottle handles (for 2- and 5-litre bottles).

There are various levels across which the Uttarakhand investment (unit III) will prove value-accretive.

One, the Company entered the manufacture of preforms and bottle handles through unit III at Uttarakhand, widening the products portfolio.

Two, the commissioning of Unit III will create a manufacturing presence for the Company in North India, which will facilitate a deeper entry into the markets of Uttar Pradesh, Rajasthan, Haryana, Himachal Pradesh and Uttarakhand.

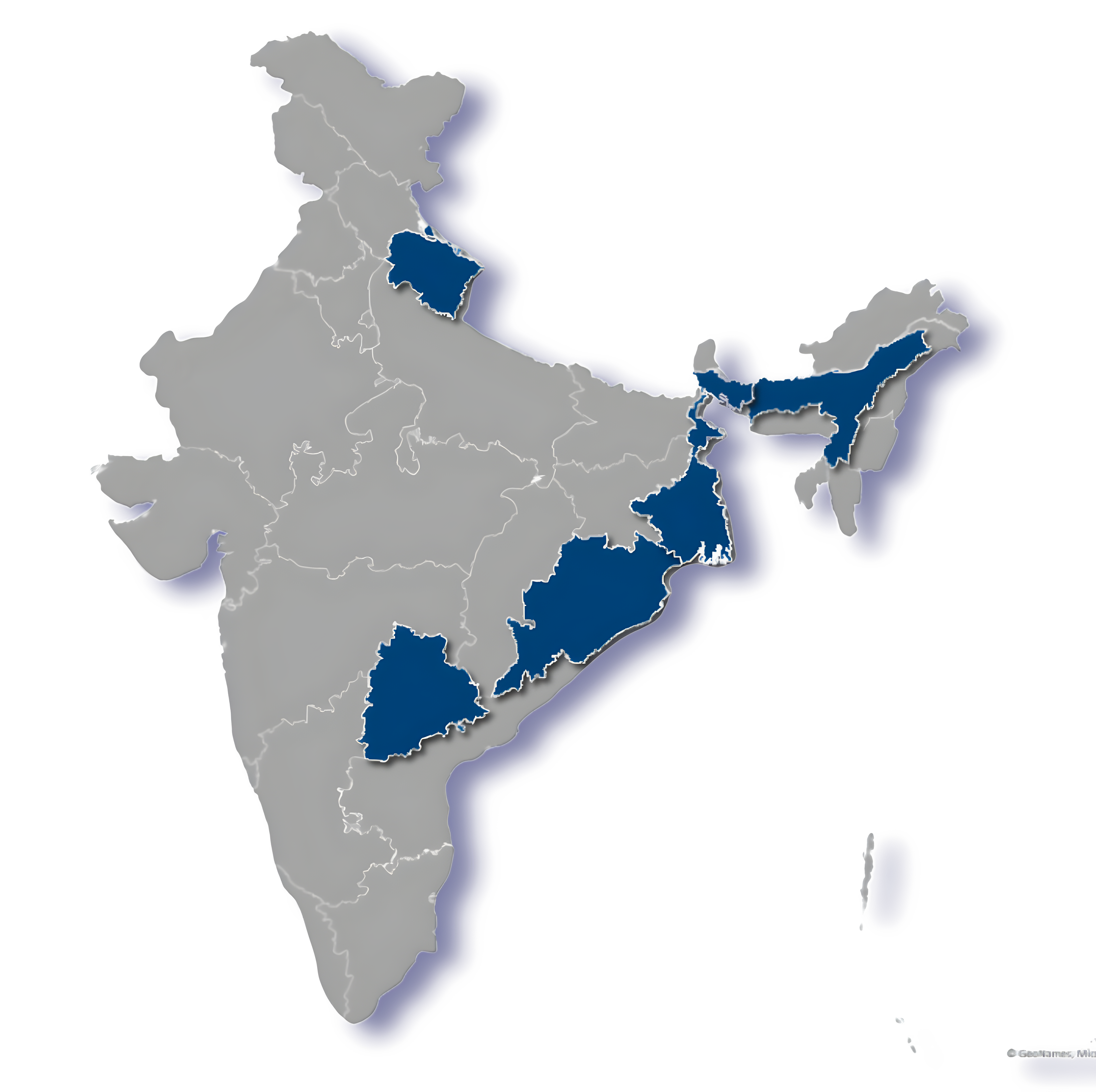

Three, the success of this unit is prompting the Company to clone similar multi-product units in different parts of India. This approach could transform the dynamics of the sector with the emergence of selfcontained units servicing the complete needs of downstream customers.

Four, the investment proved attractive considering that the Company already possessed existing land, which moderated the overall outlay, besides, the investment attracted capital, power and investment subsidy from the government, which helped moderate the break-even point, strengthen cash flows and accelerate reinvestment.

The Company’s consolidated debt-equity ratio for long-term borrowing was 1.2x as on 31st March 2023 compared to 0.84x as on 31st March 2022. The Company intends to borrow additionally during the current financial year to fund ongoing capacity expansions and there is a possibility the gearing may increase further. It would be necessary to communicate to shareholders that the Company is addressing an unprecedented sectorial opportunity with possibly the most aggressive capital spending programme within its sector; we consider debt mobilisation to be integral to our investment plan.

One : Most players in our sector are single location players, seeking capacity scale over geographical spread.

Two : Most players would rather invest in their needs of the day.

Three : Most players in our sector have invested in tax-normal locations.

Four : Most players in our sector have selected to specialise in the manufacture of single products.

Five : Most players in our sector are engaged in addressing some of the needs of the day.

The Company has embarked on an aggressive manufacturing programme at various locations in India. We believe that the cumulative impact of these expansion programmes is expected to enhance manufacturing revenues

substantially.

By commissioning relatively large capacities, we have achieved two things; one, economies of scale from day one; two, the capacity to service growing needs of a large potential customer base. Besides, each of our manufacturing facilities has been future-proofed with large available space that provides us with a growth runway in the same location for years. Each time we grow in the location, there is a possibility of doing so with speed and at an infrastructure cost that has largely been expended. In view of this, each time we expand at the same location, the more value-accretive our investment is likely to be.